Optical Metrology System Improves Alignment of Military Vehicle Performance

Optical Metrology System – Micro Alignment Telescope

Generally, the problem arises in the modern light armoured tracked vehicles travel at fast, it is essential that the track drive shaft bearings are in good alignment condition and the track suspension rollers are parallel to each other and which are aligned square to the drive axis. Failure in the alignment that causes excessive wear and vibration, breakage of the track and damage to the vehicle. These kinds of errors are identified only on the testing ground when considerable dismantling must be carried out before the error can be fixed.

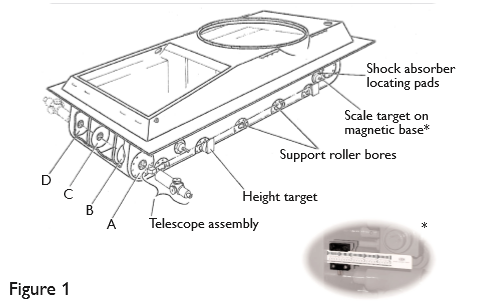

Taylor Hobson designed and manufactured the optical metrology system – micro alignment telescope equipment which can be used for checking the alignment at the beginning of manufacture, as soon as the position of bores has been machined in the hull. The drive is placed between bores B and C, is taken to the two tracks independently via driveshafts passing through bores A, B, C, and D. Conventional alignment techniques are applied to test the proper alignment of these bores, using telescope positioned centrally in bore A.

An optical square on the end of the telescope bridged a right angle line of sight down the side of the hull. The faces of the track suspension bores are verified for distance from this line by sighting on a scale and then the height of the bores with respect to the main track drive shafts is checked.