Revolutionary Impact: How Laser Cleaner Technology Prolongs the Lifespan of Machinery

In the midst of our ever-evolving technological landscape, one innovation that has quietly revolutionized numerous industries is the advent of laser cleaner technology. Much more than just an intriguing concept, this development offers transformative implications particularly in the realm of machinery maintenance and longevity.

What is Laser Cleaner Technology?

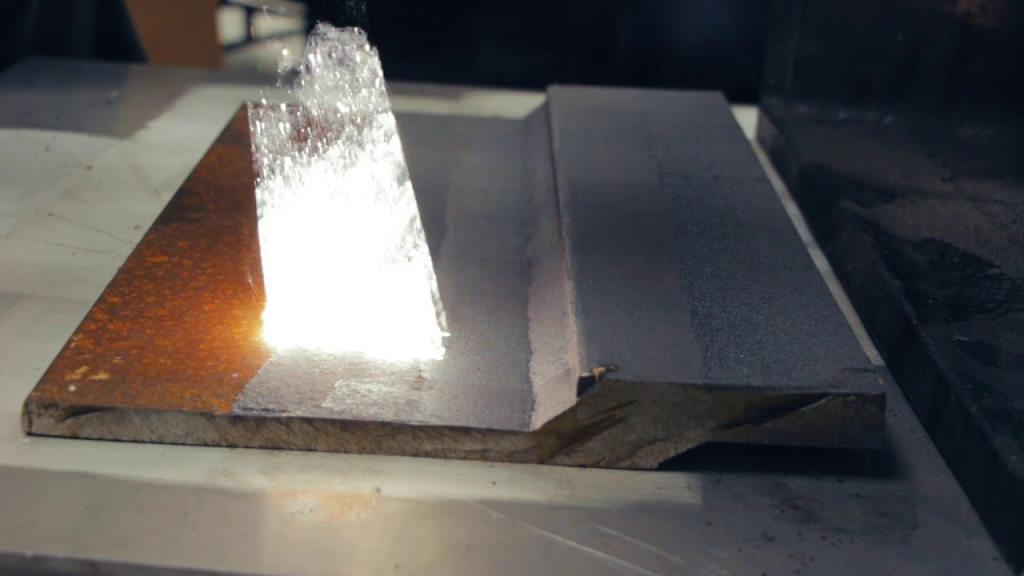

Laser cleaner technology, also frequently referred to as laser ablation, is a cutting-edge method used to remove contaminants or coatings from surfaces through the employment of laser irradiation. It functions on the principle of absorption where the laser’s high-energy light beam gets absorbed into the surface contaminants or coatings. This absorption subsequently results in the evaporation or sublimation of the unwanted material, leaving the underlying surface unscathed. In essence, the laser cleaning system has emerged as a vital tool for non-abrasive, non-contact, and precise surface cleaning, impacting numerous sectors including, but not limited to, automotive, aerospace, cultural heritage preservation, and the machinery industry.

How Does Laser Cleaning Affect Machinery Lifespan?

When it comes to the machinery lifespan, laser cleaning technology has fundamentally shifted the paradigm. Its non-intrusive nature paired with its efficiency grants this technology the ability to significantly enhance the durability and operational longevity of machinery.

Improved Precision and Efficiency

One of the principal ways laser cleaning technology impacts machinery lifespan relates to its inherent precision. Traditional methods of machinery maintenance often involve abrasive materials or chemicals, which may damage essential components and hasten wear and tear. With laser cleaning, however, this concern is virtually eliminated. Its highly targeted application ensures that only the unwanted materials are removed, preserving the integrity of the machinery.

Moreover, it also eliminates the need for disassembly of machinery parts in many cases, reducing downtime and improving overall operational efficiency. This careful approach reduces the risk of premature failure, enhancing the lifespan of the machinery.

Environmentally Friendly Approach

Laser cleaning is also recognized for its eco-friendly characteristics, an often overlooked factor that significantly contributes to the longevity of machinery. Traditional cleaning methods often rely on chemical solvents, which can cause corrosion or other damage over time. In contrast, laser cleaning operates without any such hazardous substances, thereby reducing the risk of long-term, environmentally-induced damage.

Substantial Benefits of Laser Cleaning Technology in Machinery Maintenance

The myriad advantages of implementing laser cleaning technology in machinery maintenance have been recognized in several sectors. From its non-abrasive nature to its precision, efficiency, and environmental friendliness, the benefits are substantial.

Extended Machinery Lifespan

The primary benefit of laser cleaning technology in machinery maintenance is the extension of the machinery’s lifespan. By mitigating the risk of damage from abrasive cleaning methods, and providing a precise and efficient alternative, machinery can enjoy a significantly extended operational life.

A study conducted by the Fraunhofer Institute for Laser Technology ILT in 2017 here demonstrated that laser cleaning could extend the lifespan of industrial components by up to 30%.

Cost-Effective Maintenance

In addition to the extension of machinery lifespan, laser cleaning also offers cost-effectiveness. With its capacity to eliminate the need for replacement parts and downtime, the financial implications can be significant. Businesses can anticipate reduced maintenance costs and enhanced return on investment (ROI) over time.

The Future of Laser Cleaning Technology in Machinery Maintenance

Looking ahead, the impact of laser cleaning technology on machinery lifespan promises to be profound and expansive. As this technology continues to mature and evolve, its applications within machinery maintenance are likely to grow in tandem.

Integration with IoT and AI

One intriguing prospect on the horizon is the integration of laser cleaning technology with other cutting-edge innovations such as the Internet of Things (IoT) and Artificial Intelligence (AI). By combining the precision of laser cleaning with the analytical power of AI and IoT, machinery maintenance can be further optimized. Real-time tracking of machinery conditions and predictive maintenance could become commonplace, extending machinery lifespan even further.

Expansion to a Broader Range of Industries

In addition to these technological advancements, laser cleaning technology is also expected to penetrate a wider range of industries. Industries that have traditionally relied on manual or chemical cleaning processes stand to benefit immensely from this non-abrasive and eco-friendly solution. From the medical field to the food and beverage sector, the potential applications of laser cleaning are vast and varied, offering the promise of enhanced machinery lifespan across the board.

Embracing Laser Cleaning Technology for Long-Lasting Machinery

Given its transformative potential, it’s not surprising that laser cleaning technology is rapidly gaining traction in various sectors. As we’ve seen, its contribution to extending machinery lifespan is substantial and undeniable.

The precise, efficient, and eco-friendly nature of laser cleaning makes it an ideal solution for machinery maintenance. Its capacity to reduce downtime, lower maintenance costs, and prevent damage to machinery components positions this technology as a pivotal tool in promoting long-lasting machinery.

Moreover, the future promises further advancements, with possibilities like AI and IoT integration and expansion to a wider range of industries. For businesses and industries seeking to optimize their machinery lifespan, embracing laser cleaning technology is a forward-thinking and strategic move.

In conclusion, the impact of laser cleaning technology on the lifespan of machinery is nothing short of revolutionary. It signifies a paradigm shift in machinery maintenance and presents a promising outlook for various industries’ long-term operational success. In the face of such compelling advantages, the choice to adopt laser cleaning technology seems not just viable, but indeed, inevitable.