Precision Manufacturing with Hot Chamber Die Casting

All engineering and manufacturing processes start with a concept. The concept is what gets turned into the actual product or component used in the factory to produce other goods or as a component of a mechanical part such as a vehicle part or an engine.

Engineering requires the use of high-precision designs and manufacturing processes to ensure that the product is safe for use. No matter the application area, precision is essential and is one of the critical aspects of any design or prototype.

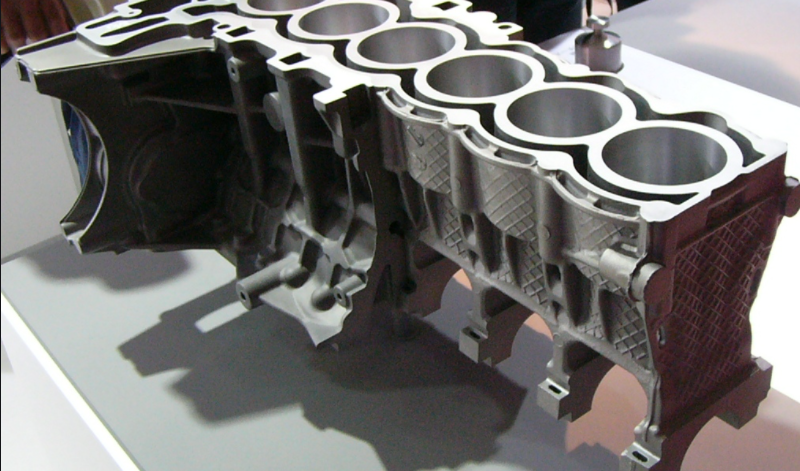

Modern prototypes require the best manufacturing processes that are accurate and made from high-quality products. Hot chamber die casting is a method used for different manufacturing processes. It makes use of alloys that require lower temperatures to melt, such as magnesium and zinc. This way, the precise manufacturing of die-cast products is made possible.

The process uses the molten metal in a chamber that is also part of the hot chamber die casting machine. Once the molten metal has been put into the chamber, it is exerted to high pressure to ensure that it is securely in place and has taken on the desired shape.

This high precision process brings out the best prototypes, which are essential in both engineering and manufacturing. The molten metal is left for a while to solidify, resulting in the actual component that you would like to produce.

The process is not only cost-effective but is also highly streamlined, which means that you will be able to produce high quantities of components.

For instance, gear that must be precisely engineered must be manufactured to precise dimensions to ensure that you get the best results. see more here https://www.ekoindustries.com/precision-die-casting/hot-chamber-die-casting/, is essential for both commercial and industrial products designed from scratch. It is an effective way of manufacturing all the concepts that you could think of, and the fact that you get high levels of precision means that you will be able to design better products.

Whenever you have a design that requires a considerable number of components, such as gears and wheels, the use of this process will ensure that you get the best result and get your finished product assembled much faster.

We have the processes and manufacturing techniques for you whenever you need to produce high amounts of the same component.

We will not only ensure that you have the components you need, but we will also make use of your designs to manufacture the components. The hot chamber die casting process is one of the most advanced manufacturing industries and is ideal for your prototyping needs. When you are working on a new design for a component to be used for your varied needs, this process will get you the individual pieces and components which will then be used for the final machine you have been designing.

Our years of experience and the high precision we use for our die casting ensure that you do not have to deal with low-quality components. Make your engineering creations more quickly and efficiently with our reliable and accurate services.