Safety Measures To Follow While Using Hydrocarbon Extraction Machine

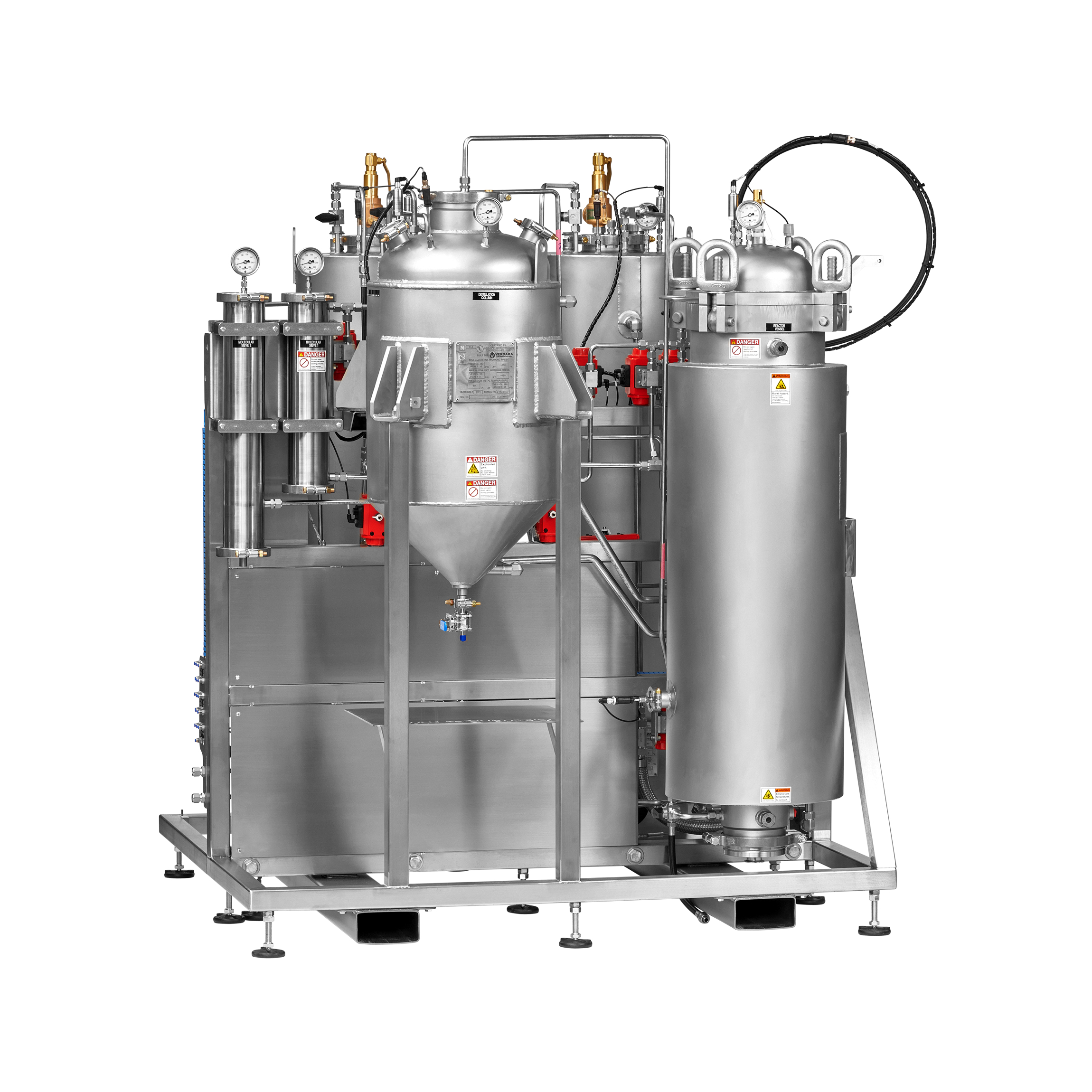

Hydrocarbon extraction machines are widely used in the cannabis and hemp industries to extract valuable compounds like cannabinoids and terpenes from plant material. While these machines are efficient and effective, they also come with potential safety risks due to the flammable and volatile nature of hydrocarbon solvents like butane and propane. It’s essential to follow strict safety measures to ensure the well-being of both operators and the facility. Here are some crucial safety measures to adhere to while using a hydrocarbon extraction machine:

- Proper Training and Certification

Before operating a hydrocarbon extraction machine, ensure that all personnel involved in the process are adequately trained and certified. Training should cover the machine’s operation, emergency procedures, safety protocols, and the proper use of personal protective equipment (PPE).

- Ventilation and Gas Detection Systems

Install a well-designed ventilation system that can effectively remove any flammable gases, vapors, and fumes from the extraction area. Proper ventilation is critical in preventing the accumulation of potentially explosive gases in the working environment. An efficient ventilation system should provide constant airflow to ensure that any hazardous gases are quickly diluted and carried away from the extraction area. In addition to ventilation, it’s essential to implement reliable gas detection systems within the extraction facility.

- Explosion-Proof Equipment

Ensure that all equipment used in the extraction process, including the machine itself, is explosion-proof and compliant with safety standards. Explosion-proof equipment is designed to prevent sparks, arcs, or heat that could potentially ignite flammable gases. When operating a hydrocarbon extraction machine, investing in explosion-proof components is a fundamental step in minimizing the risk of fire or explosions.

- Emergency Shutdown Procedures

Train operators on how to perform emergency shutdown procedures in case of any malfunction, leak, or potential hazard. This includes shutting down the extraction machine, turning off gas supplies, and evacuating the area if necessary.

- Personal Protective Equipment (PPE)

Provide and mandate the use of appropriate PPE, including flame-resistant lab coats, safety goggles, gloves, and closed-toe shoes. This protective gear can help minimize the risk of exposure to flammable solvents and potential ignition sources.

- No Open Flames or Sparks

Strictly prohibit open flames, sparks, smoking, or any potential ignition sources in the extraction area. Even seemingly small sparks can ignite flammable gases and lead to dangerous fires or explosions. Designate the extraction area as a no-smoking zone and enforce this rule rigorously. Eliminate any unnecessary electrical equipment that could generate sparks, and ensure that all electrical connections are properly sealed and insulated to prevent the risk of electrical arcs. You should follow similar security protocols while using other extraction machines like the Butane extraction machine.

- Static Electricity Control

Implement static electricity control measures, as static charges can accumulate and discharge in hazardous environments. Grounding all equipment and using anti-static mats can help prevent static-related incidents. Additionally, ensure that employees wear appropriate static-resistant clothing to further mitigate potential risks.

- Regular Inspections and Maintenance

Conduct regular inspections and maintenance on the extraction machine to ensure that all components are in good working condition. Regular maintenance can help identify and address potential issues before they become safety hazards.

- Fire Suppression Systems

Install fire suppression systems, such as automatic fire extinguishers or sprinklers, in the extraction area to quickly contain fires in case of an emergency. Regularly inspect and maintain these systems to ensure their effectiveness and reliability. These systems swiftly contain fires, bolstering safety protocols. Regular inspections sustain their effectiveness.

- Emergency Response Plan

Devise a detailed emergency response plan that encompasses well-defined evacuation routes, clear and efficient communication protocols, as well as meticulously outlined procedures tailored to address a spectrum of potential emergencies. This includes effectively managing situations like leaks, fires, or chemical spills with utmost precision and safety measures.

- No Unauthorized Personnel

Establish stringent access limitations exclusively for authorized personnel within the extraction area. Employ prominently visible signage and deploy robust access control mechanisms to effectively thwart any unauthorized entry attempts. Enhance security through conspicuous signage and deploy advanced access control measures, fortifying safeguards against any potential breaches by unauthorized individuals.

- Chemical Storage

Store hydrocarbon solvents, as well as other chemicals, in designated storage areas that are well-ventilated and away from potential sources of ignition.

- Safety Data Sheets (SDS)

Maintain up-to-date safety data sheets for all chemicals used in the extraction process. SDS provides essential information about the hazards, safe handling, and emergency procedures for each chemical.

- Training and Drills

Regularly conduct safety training sessions and emergency drills to ensure that all employees are aware of proper safety protocols and know how to respond effectively to different situations.

Wrap Up

By following these safety measures, operators can significantly reduce the risks associated with using hydrocarbon extraction machines. Prioritizing safety not only safeguards the well-being of personnel but also helps protect the facility from potential accidents, fires, and explosions.