The Importance of Reliable Medication Supplies for Hospitals

In an era defined by advancements in medicine and patient care, the cornerstone of any successful healthcare system lies in the consistent availability of medications. Without them, treatments halt, and lives hang in balance.

The silent corridors of hospitals speak volumes about the dynamics of patient care, where each medical intervention is a calculated decision. At the heart of this complex web is the constant supply of essential drugs, playing a pivotal role in shaping positive patient outcomes.

Yet, the magnitude of this silent operation often goes unnoticed until disruptions occur. Whether it’s a break in the supply chain, manufacturing delays, or global shortages, the consequences are immediate and severe. And while healthcare professionals strive to ensure seamless patient care, the system’s robustness is truly tested when medications become scarce.

In the ensuing sections, we explore the intricacies of this vital component, shedding light on its significance, challenges, and the role industry pioneers play in ensuring that hospitals never run dry of essential medications.

The Domino Effect of Drug Shortages

Imagine a busy hospital where surgeries are scheduled, treatments are ongoing, and patients rely on timely interventions. Now, visualize a sudden shortage of a critical drug. The ripple effect is immediate: procedures are postponed, alternative treatments are sought, and clinical outcomes become uncertain.

Such situations aren’t mere hypothetical scenarios; they’re real challenges that hospitals face. And in these trying times, the importance of a consistent medication supply is felt more than ever. The stakes are high, with patient lives and healthcare reputations on the line.

Naturally, the immediate response involves seeking alternatives, but these might not always align with the best patient care standards. Substituting drugs or altering dosages introduces variables that weren’t accounted for in the original treatment plans, potentially compromising patient outcomes.

Moreover, the financial implications of drug shortages are profound. Hospital resources are stretched thin, operational costs spike, and the very essence of efficient patient care is threatened. As healthcare administrators grapple with these challenges, the quest for a more reliable drug supply becomes paramount.

Navigating the Challenges of Global Supply Chains

In our interconnected world, the production of medications is a global affair. Ingredients sourced from one continent may be processed in another and consumed in a third. While this global supply chain offers benefits like cost efficiencies, it also introduces a myriad of challenges.

One significant challenge lies in the sheer complexity of these chains. With multiple players involved, each step becomes a potential point of failure. Be it geopolitical tensions, logistical hiccups, or quality control issues; the threats are manifold.

Furthermore, the recent pandemic underscored the vulnerabilities of over-reliance on a single region for critical medications. As nations went into lockdown and production facilities shuttered, the fragility of the global supply chain was laid bare. Hospitals across the world felt the pinch, highlighting the need for diversification.

In this maze of global networks, certain pioneers stand out, reshaping the pharmaceutical landscape. One such entity is Medivant Healthcare. Located in Phoenix, Arizona, Medivant Healthcare offers a beacon of hope with its state-of-the-art facilities, ensuring the consistent, reliable production of generic medications. Embracing full automation and adhering to stringent cGMP processes, they exemplify the next generation of American manufacturing, ensuring that healthcare providers have access to essential drugs, even in times of global disruptions.

The Evolving Dynamics of Pharmaceutical Manufacturing

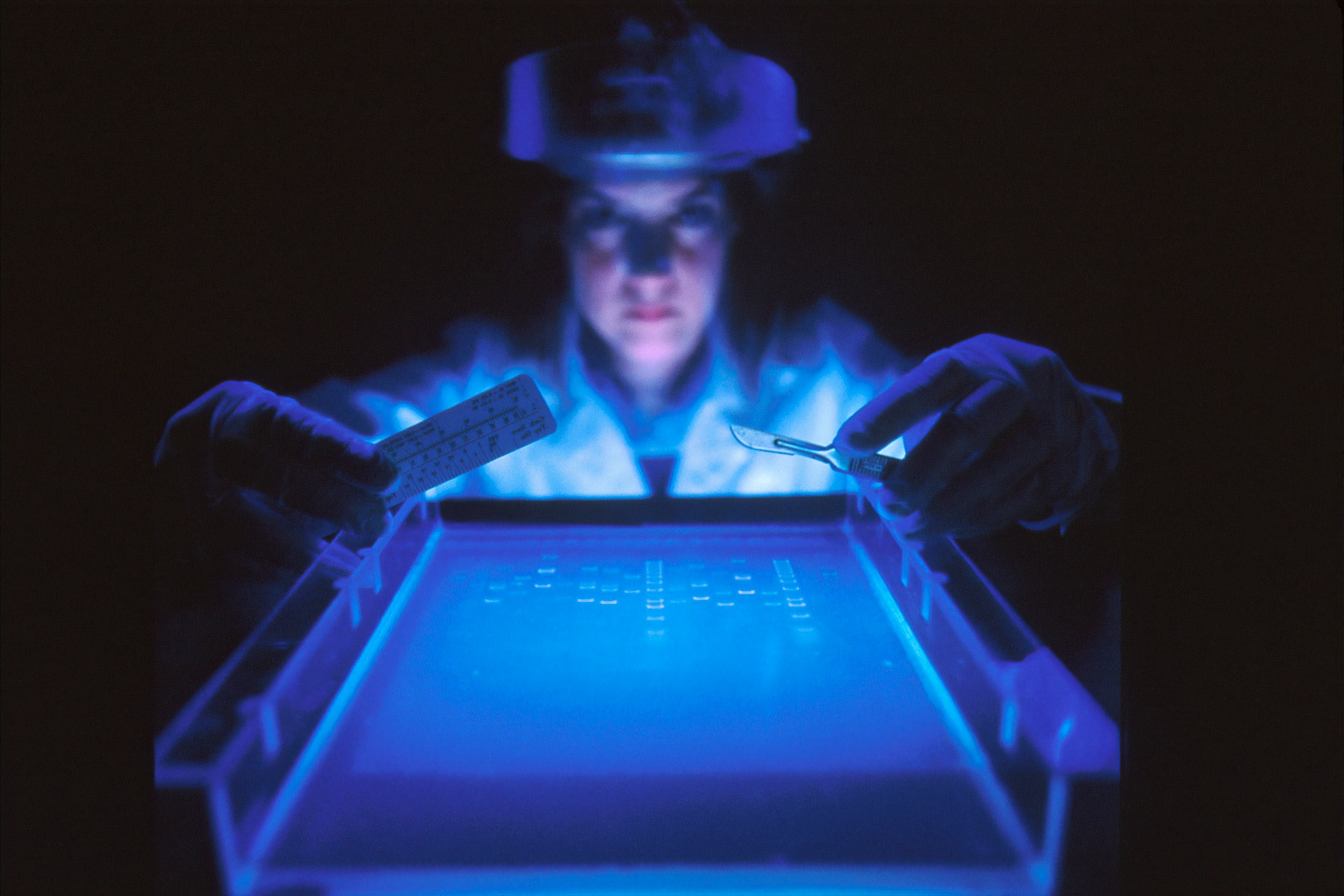

The pharmaceutical industry has come a long way from its rudimentary beginnings. Today, it stands as a complex interplay of science, technology, and logistics. Key to its evolution has been the integration of advanced automation processes, enhancing both efficiency and precision.

Within this advanced manufacturing landscape, the emphasis on quality cannot be understated. Every medication that reaches a patient undergoes a rigorous journey, being scrutinized at each step to ensure it meets the highest standards. And as patient demographics shift and demands evolve, the industry must adapt, ensuring that it not only meets but anticipates future needs.

The role of automation in this transformation is pivotal. Modern facilities, equipped with cutting-edge technology, can produce medications at scales previously deemed impossible, all while maintaining impeccable quality. This mass production capability becomes especially crucial when addressing widespread health concerns that require vast amounts of medications in short durations.

But, as with any significant change, challenges arise. Training personnel, ensuring seamless integration with existing processes, and maintaining stringent quality control amidst increased production rates are just some hurdles the industry faces. Yet, with pioneers leading the charge, the future of pharmaceutical manufacturing appears promising.

Quality Assurance: More Than Just a Checkbox

In the realm of medications, quality isn’t a luxury—it’s a necessity. Every drug, every vial, and every pill holds the promise of better health, and compromising on quality can have dire consequences. This is where robust quality assurance mechanisms come into play, serving as the industry’s watchdogs.

To comprehend the depth of these processes, one must understand the myriad factors influencing drug quality. From raw material sourcing to production, storage, and transportation, each phase poses unique challenges. Addressing these requires a blend of technology, expertise, and a culture that places quality above all.

Quality assurance isn’t a static endeavor. As new research emerges and technologies evolve, the benchmarks for quality shift. This dynamic nature demands constant vigilance, ensuring that medications align with the latest medical standards and patient needs.

An integral component of this assurance process is the robust supply chain. Ensuring that raw materials are sourced responsibly, storage conditions are optimal, and transportation logistics are streamlined plays a crucial role in guaranteeing drug quality.

The Patient at the Center: Ensuring Affordability and Access

While the quality and reliability of medication supplies are paramount, they must also be accessible and affordable. After all, the best medications serve little purpose if they remain out of reach for those in need.

Healthcare systems globally grapple with the challenge of ballooning drug prices. Several factors contribute to this, from research and development costs to regulatory hurdles and market dynamics. Yet, amidst these challenges, the focus must remain on the patient, ensuring they receive the best care without financial strain.

Innovative solutions are emerging to address this conundrum. From generic medications that offer affordable alternatives without compromising on quality, to streamlined production processes that cut costs, the industry is evolving to put the patient first.

Moreover, collaborations between pharmaceutical companies, healthcare providers, and policymakers can pave the way for more sustainable pricing models. By working together, these stakeholders can ensure that the fruits of medical advancements reach all, irrespective of their financial standing.

Preparing for the Future: Adapting to a Changing Landscape

As with any industry, the pharmaceutical sector is in a state of constant flux. Emerging diseases, evolving pathogens, and shifting patient demographics all influence the medications that hospitals require.

To stay ahead of this curve, a proactive approach is essential. This means not just responding to current needs but anticipating future challenges. From investing in research and development to expanding production capacities and diversifying product portfolios, preparation is key.

Emerging technologies also offer exciting possibilities. The integration of artificial intelligence and machine learning can provide insights into drug demand trends, enabling manufacturers to adjust production accordingly. Additionally, these technologies can aid in drug discovery, potentially revolutionizing treatment paradigms.

Yet, amidst this forward-looking approach, the core tenets of the industry must remain intact. Quality, reliability, and patient-centricity should always be at the forefront, guiding the sector’s evolution and ensuring that hospitals consistently receive the medications they need.

The Path Forward

In understanding the importance of reliable medication supplies for hospitals, one thing becomes clear: it’s a collective endeavor. From pharmaceutical manufacturers to healthcare providers, policymakers, and patients, each stakeholder plays a vital role.

The challenges are undeniably significant. Yet, with collaboration, innovation, and a relentless focus on quality and patient care, the industry stands poised to meet them head-on. The future of healthcare hinges on the consistent availability of medications.

By ensuring that every vial, every pill, and every dose is produced with precision, care, and an unwavering commitment to quality, the pharmaceutical sector not only supports hospitals but upholds the very ethos of healthcare: to heal, to care, and to make a difference, one patient at a time.